Adiva provides a rich design analysis toolset tailored to a designers needs. By using the baseline ADIVAnet, a designer can verify component connection integrity in a quick, simple Netlist Compare process; a virtual bare board electrical test. Upgrading to ADIVAdrc provides three levels of PC Design checking, Quick Check, Design Check and a fully Custom Check to meet any designer's analysis needs. Followup for design analysis is ADIVAview used by design engineers, fabricators, assemblers and quality control alike providing best in class design review tools.

ADIVAnet

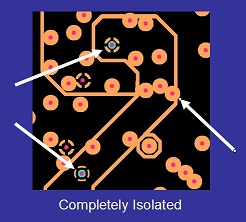

It is far easier to resolve a net connectivity error before product release. With ADIVA's Virtual Netlist Checking tool, ADIVAnet, designers can simulate the manufacturing netlist test process of a finished board during the design process. This verifies electrical integrity of design data before it is released to fabrication.

ADIVAdrc

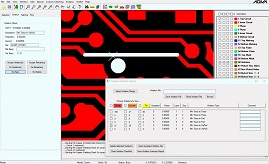

It is far easier to resolve a design mistake before product release. Whether it is a connectivity issue, library issue, routing issue or manufacturability issue, we are all human and mistakes happen. Some are generated by the host CAD software, some are created by the designer or librarian, some are created through simple misunderstanding, some from poor procedures or even lack of training. The worst mistakes are created while making changes at the last minute - rushing to ship the design.

ADIVAview

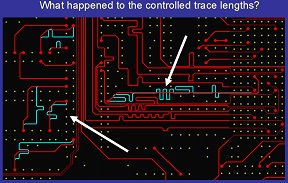

ADIVAview is an intelligent, independent, easy to use PCB design and artwork review tool. A wealth of information is derived and displayed from combined Manufacturing and CAD Design data. Highlight nets and net groups to display their routing or highlight components for placement review. With two data sets, different design revisions can be compared, analyzed, with differences displayed for easy review.